Robin Baxter: G7 Color Management Expert

Last week, one of Carter Printing Company’s prepress technicians, Robin Baxter, went through online training for her G7 Expert Certification.

It is no question that colors look different on the screen than when they are printed on paper. Even then the colors vary from printer to printer. In 2006, Don Hutcheson, the head of the International Digital Enterprise Alliance – Idealliance- created a method to help minimize color difference between computers and the various printers being used. He aimed to neutralize color shade differences from computers to plate printing (CtP). When broken down to the basics, the process is a way of balancing grayscale tones and setting a standard that allowed any press to match the tonality and gray balance of any cmyk printing or proofing system. He called the process “P2P” for proof-to-press or press-to-proof.

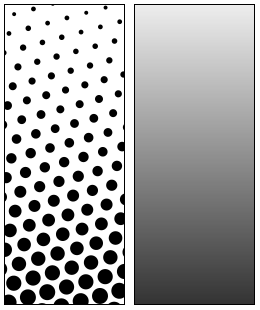

A method was developed by using mathematical equations, complex software, and a multitude of graphs to average ISO standard press runs made with uncalibrated plates to develop the new GRACoL 2006 color space. On offset presses colors often print darker than desired due to tonal value increases (TVI) or dot gain. This is precisely the kind of problem a G7 Expert can fix. A TVI graph works in relation to the International Organization for Standardization’s (ISO) principles of half tone printing where color on paper is created by printing millions of tiny dots in different sizes close together so that without an intense magnifier the human eye sees it as a gradient.

TVI does not account for color differences. For G7 specifications, TVI is not the metric for tonality and gray balance and paper hue was not accounted for. A Neutral Print Density Curve (NPDC) takes the color of the paper and the printer’s dynamic range into account, while preserving crucial highlight tonality. The NPDC focuses on having neutral greyscales by using 2 scales to measure gray balance and tonality. A black ramp from 0-100 and a corresponding cyan, magenta, and yellow ramp. After many tests on offset presses using ISO standard ink and approved paper. The gray balance and tonality values were determined: HC (highlight contrast) c25, m19, y19; HR (Highlight Range) c50, m40, y40 and SC (Shadow Contrast) c75, m66, y66.

Robin took an intensive online course instructed by Ron Ellis, the chair of the Idealliance Print Properties Committee, and earned her place as one of the ten G7 Experts and one of six Color Management Professionals in Virginia. In her class, technicians from across the globe, using many different printing devices and substrates joined together in learning the G7 method. Students from Belgium, India, France, and other countries all learned together about enhancing colors in printing to the best it can be.

Now, Robin is tasked with a mighty mission: establishing Carter Printing Company as a G7 Master Facility.

She plans to start with bringing 2 presses into compliance by using the G7 methodology including - the offset 56” Mitsubishi press and the Epson proofers. Everyone on the Carter Printing Company team is excited for this process to begin and proud of Robin for all the work put in to achieve this certification.

For more information about the G7 process and the science behind it, see https://idealliance.org/ or read John Parsons’, Principal of IntuIdeas LLC, article on the value of G7 here.